What is Instrument Validation and Why Do I Have to Do It?

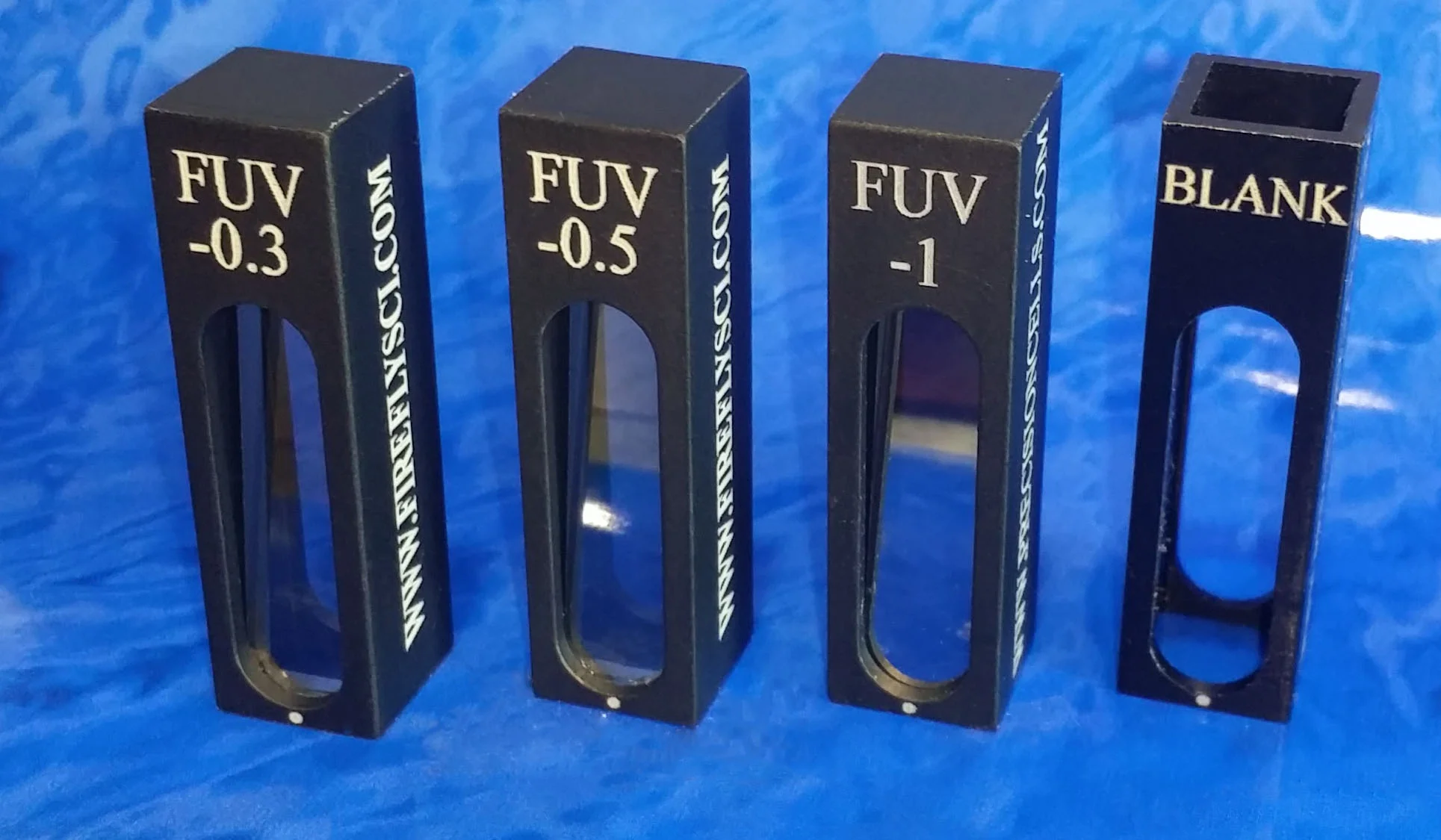

/Instrument validation done with metal-on-quarz filters

There are many products being manufactured on a daily basis. With certain products, especially those going into the medical, drug, and food industry, certain guidelines must be in place before products can be sold to the public. This is where instrument validation comes in.

What is Instrument Validation?

In a nutshell, IV is a documented process that all users of an instrument must follow. These guidelines are written in a very clear, easy to follow way so anyone can apply them. Consistency is of the utmost important when performing the validation of an instrument. The goal of the established guidelines is to make sure that all equipment is up to spec before any work is done. This allows all the operators of the equipment the peace of mind that all the work they are performing is at 100% capacity.

Why Do I have to Do Instrument Validation?

As we mentioned above, many industries has strict guidelines on what is safe and what is not safe. If a lab does not perform the proper validation procedures on their equipment and someone is hurt as a result, companies can be in for some nasty lawsuits. It is best to just take a few minutes in the beginning of the day, calibrate your equipment and be done with it.

Let’s take a look at the validation of a UV-VIS Spectrophotometer. This machine is used in many different industries ranging from DNA research to forensics. So it is super important that you validate a spectrophotometer before using it.

What Types of Instrument Validation Are Possible on a UV-VIS Spectrophotometer?

There are a number of ways to check the performance of a UV-VIS spectrophotometer such as:

- Photometric Accuracy – This type of test assures that the assigned wavelength is giving the correct reading. During the test, a calibration standard is used to test if the machine data, matches the benchmark data of the calibration standard.

- Wavelength Accuracy – This test scans a spectrum of the spectrophotometer and looks for certain peaks in the measurements. There are benchmark peaks that all machines must have and if there is a shift in the peaks, then the machine needs to be serviced.

- Stray Light – This test tells you if there is light outside of the specified wavelength that is being sent to the sample.

- Spectral Resolution

Some Notes On Optical Densities

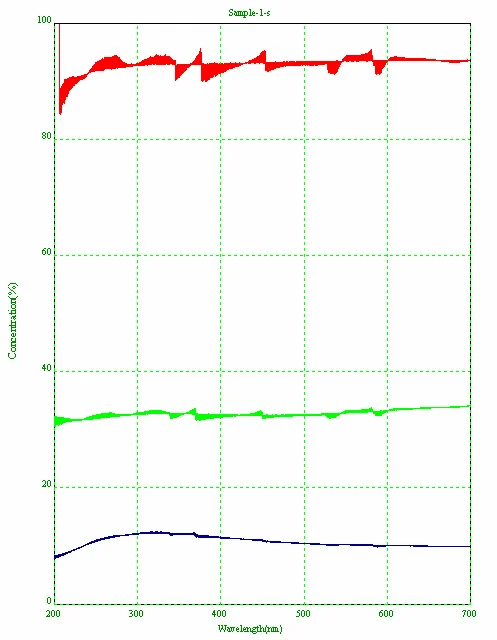

In optical spectrophotometry people analyze samples of a very wide range of optical densities - starting from 0.001A and up to >10.0A. Accuracy of spectrophotometers vary within the above range and within different wavelength regions (i.e. UV vs VIS vs NIR).

Optical Densities Chart

Since there is such a broad range of samples being tested in a spectrophotometer, instrument validation procedures require a large range of photometric calibration standards with varying optical densities.

Taking the above into consideration, for full instrument validation, we recommend that all labs have spectrophotometer calibration standards covering all photometric and wavelength ranges of samples they work with.

Important: Pharmacopoeia requirements in many countries outline only the minimum requirements for calibration standards that users must have. Therefore, bio-pharmaceutical customers still need to have in their possession calibration standards covering all photometric and wavelength ranges of samples they work with although some of these calibration standards may not be listed in the Pharmacopoeia of their country of operations.

Shimadzu has a great write up on why instrument validation is so important on a spectrophotometer, please read the information from their website below:

Here is the link to the full article.

(Taken from Shimadzu website) A spectrophotometer is made up of many components, some of which are consumables that deteriorate according to the time and frequency of operation. Instrument validation is also useful for determining the state of the constituent components of the instrument.

Let's consider the noise level as an example. The noise level is one indicator of the condition of the light source (lamp) in the spectrophotometer. The noise level is defined as the maximum deviation (maximum distance between peak and trough) of the absorbance measured over one minute at a specific wavelength near 0 Abs. Fig.3 shows the graph of a measured noise level.

As the relative noise increases when the emitted light intensity of the lamp drops off over time, the noise level becomes higher. A higher noise level means that the data reproducibility is lower. This has a negative effect when accurate photometric values are required.

When it is necessary to detect extremely small absorption peaks, it may not be possible to detect the peaks correctly if the noise level is so high that they become buried in the noise.

The optical system of a spectrophotometer contains various mirrors for focusing and forming a spectrum. The surfaces of these mirrors can deteriorate over time. It is also possible for dust and dirt from the atmosphere to adhere to the mirror surfaces due to the environment where the instrument is installed. For example, the deterioration of a mirror that forms the spectrum can be one cause of the increase in stray light described above.

Therefore, instrument validation can provide valuable information to diagnose the condition of an instrument. It is recommended to perform periodic instrument validation to continuously understand and manage the state of the instrument. It is also important to validate an instrument after consumables are replaced or the instrument is moved to a different place.

If you need to validate your spectrophotometer and need calibration standards please visit the pages below:

- Photometric Accuracy

- Wavelength Accuracy

- Stray Light

- Spectral Resolution

- Spectrophotometer Calibration Kits

Here’s to Your Success!

The FireflySci Team

![firefly_logo_FINAL [Black].jpg](https://images.squarespace-cdn.com/content/v1/5411d5c0e4b02e1c8b27565a/1434491508803-XB4OF7YDY46Z72L5U5AP/firefly_logo_FINAL+%5BBlack%5D.jpg)